Tune Hubs, Wheels & More – Lightweight Construction Made in the Black Forest

Are you looking for lightweight add-on parts for your road bike, your gravel bike or your mountain bike? Then Tune bike parts are the right choice for you! Tune hubs, wheels and bike parts are manufactured in their own production facility in the heart of the Black Forest. Every Tune product is truly handmade, with a lot of experience and just as much passion. In addition to Tune wheels, there are individual Tune hubs, handlebars, saddles and much more. Although the focus of Tune Parts is on lightweight construction, they are extremely robust and durable.

Read moreThe History of Tune

Tune is the epitome of super light bicycle components. Minimum weight with maximum function: from the very beginning, this was the clear focus of the company, which has been based in the Black Forest for more than 30 years. It all started with a problem: Tune founder Uli Fahl still had a normal job at the time. On weekends, he went climbing in the Alps with his wife – by bike. On the way, he realised that he was using up more energy than he would have wished. Among other things, his aluminium bike, which was much too heavy, was to blame. That was at the end of the 1980s, when the mountain bike boom was just spilling over into Europe. At that time, mountain bikes didn't have much to do with lightweight construction.

This was soon to change, as Uli Fahl began to tinker. He replaced all the heavy bolts on his bike with lightweight aluminium ones. He developed weight-optimised rear derailleur kits and a super-light quick release. This was his breakthrough. Suddenly Uli Fahl was known throughout the bike world. He seized the opportunity, quit his job and founded Tune.

The Tune Philosophy

Since the founding of Tune, the focus of all products has been on weight. Nevertheless, no compromises are made in terms of stability. On the contrary: every Tune product has to pass tough tests before it is launched on the market. The result is products that are extremely light and can take a lot of punishment. It is not without reason that Tune mountain bike wheels helped multiple German downhill champion Marcus Klausmann to his legendary successes for years.

Apropos Tune wheels: They are without a doubt the showpieces of the component forge from the Black Forest. One thing was clear to Tune founder Uli Fahl: it makes a lot of sense to save weight on the wheels. Every gram less is noticeable on the rotating mass. No wonder that Tune today offers numerous wheel models for every area of use and for every budget.

Tune and Sustainability

Tune is based in the middle of the Black Forest. Company founder Uli Fahl has always been close to nature. That is why it is important to him to produce in a way that conserves resources and is as environmentally friendly as possible. For this reason, a large part of the electricity demand is covered by the company's own solar system. Production waste, especially that from machining, is completely recycled. Product packaging is designed to be plastic-free and shipping cartons are reused several times. The production itself is extremely sustainable: It takes place entirely in Germany. Tune bike parts are of high quality and accompany you much longer than many others. In the event of a defect, you can get spare parts for the repair of most Tune bike components.

Tune and the Names

Minimalism is deeply anchored in Tune's corporate DNA: getting as much benefit as possible from as little material as possible is the thing of the likeable company from the Black Forest. This principle is also applied to the choice of names. Tune product names are short and crisp. So the Tune bicycle components named minimalist, to the point and often spiced with a pinch of double meaning. The Link Carrier, for example, is a bottle cage with side access for exceptionally compact frames. The Geweih is the carbon dropbar from Tune, while the straight MTB model has been named Turnstange. Less is sometimes more. This also applies to the names of Tune bicycle parts.

Tune Products – an Overview

If you want to tune your bike, the Tune components are the right choice. The Black Forest company has many parts for mountain bikes, road bikes and gravel bikes in its range:

- Tune hubs

- full Tune wheelsTune wheels for road bikes

- Tune wheels for mountainbikes

- stems

- handlebars

- headsets, Aheadset starnuts and spacers

- seat posts

- Tune saddles

- seat post clamps

- freewheel bodies and spare parts

- bottle cages

- bottles

- quick releases

- thru axles

- Tools and accessories such as the Tune salt shaker or the tamper for portafilter – both made from converted hub bodies.

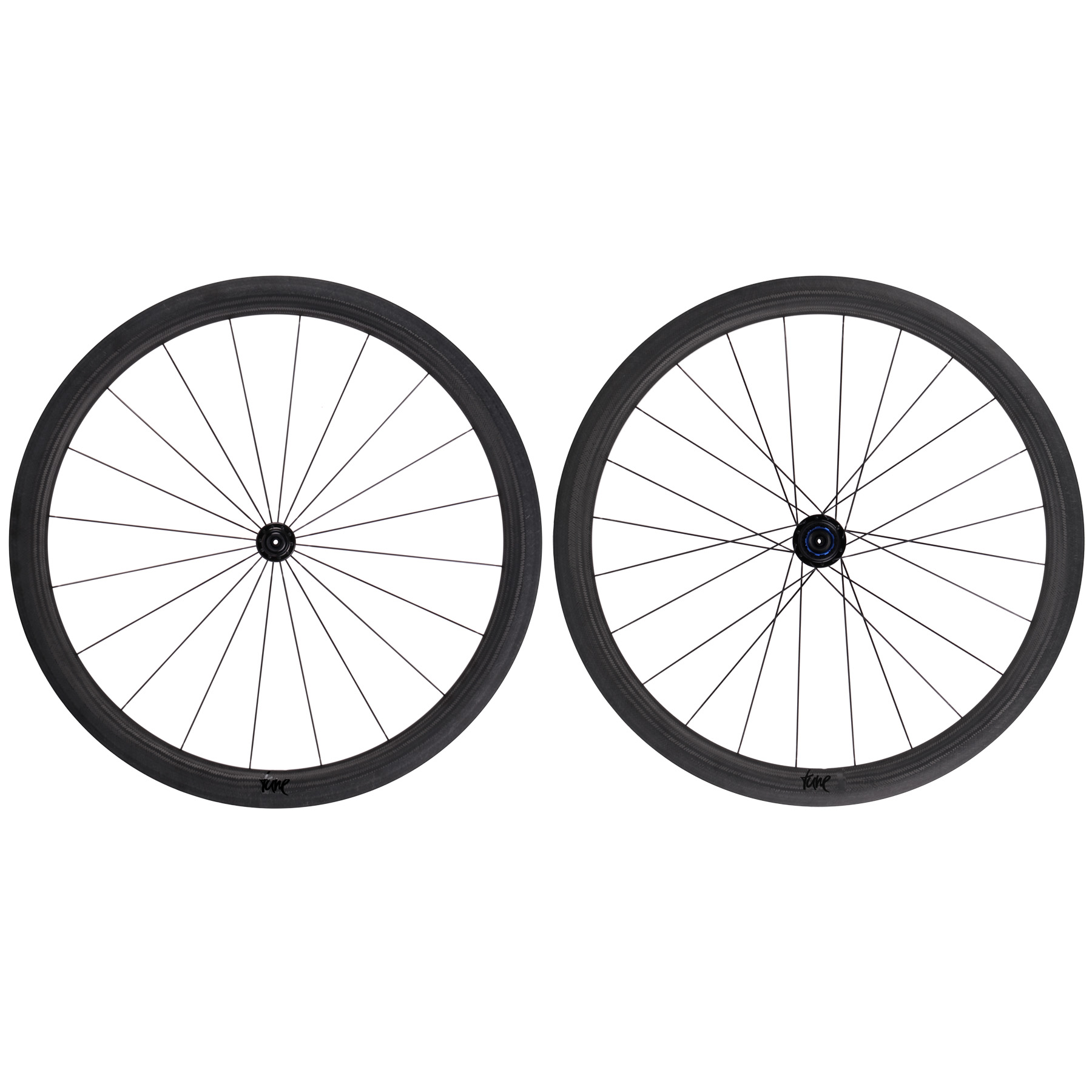

Tune Wheels

The selection of Tune wheels is large. There are Tune wheels with aluminium rims and those with carbon rims. Both variants are available for disc brakes and rim brakes in the road bike range. The Tune gravel wheelset and mountain bike wheels are only available with disc hubs. We recommend the TSR22 aluminium wheelset for those who want to save money on road bikes. It is incredibly light and extremely attractively priced. The carbon versions of the Schwarzbrenner wheels are a visual treat for all roadies.

Gravel wheels from Tune go by the name of Crosser. You decide whether you want a Tune Crosser Aluminium or a Tune Crosser Carbon. You also have the choice of 650B or 700C.

The aluminium models for mountain bikes are called Race and are available in all possible versions. There is even a model to match the Cannondale Lefty suspension fork. The Race models are robust and recommended for enduro use. Tune mountain bike wheels with carbon rims are called Blackburner. They are only available in 29 inch and are primarily intended for cross-country use. To find the right wheel for you, use our filter function.

Tune Wheelsets: Handmade in Black Forest

All Tune wheels are handmade at Tune in the Black Forest. Many steps are involved before the finished Tune wheelset can go on sale. First, the spokes are laced into the Tune hubs and brought together with the rim. Then the spoke nipples are pre-tensioned. To pre-tension the Tune wheel, the spoke tension is slowly and evenly increased. The final fine truing is done exclusively by hand. In between, the wheel is pressed down so that the spokes can settle. All this takes a lot of time. The result is a highly precise and extremely durable wheel.

Tune Hubs

All Tune hubs are produced in Tune's own CNC production. 3D CAD models "translate" their data for the CNC machines, which then mill finished components of the highest quality from an aluminium block. Did you know that a hub body weighing approximately 70 grams is made from an aluminium block that originally weighed one kilo?

The result are classy hubs for road bikes, cyclo cross, gravel bikes and mountain bikes. Tune produces countless model variants for all possible standards. There are Tune hubs for the Shimano Centerlock system, hubs with 6-hole disc mountings, Tune hubs for the Boost standard and hubs for normal installation widths. Tune has the right hub for every application and for every standard. By the way, Tune hubs are easy to repair. You can also convert any 17 mm Tune hub if you need a different hub standard. In this way, a Tune hub is an extremely sustainable investment.