Bike Spokes & Nipples

Bicycle Spokes and Nipples – Small Parts With a Big Impact

Bicycle spokes and nipples are two bicycle parts that hardly any bike can do without. The reason for this is simple: bicycle spokes connect the hub to the rim via matching spoke nipples. Specifically, the spokes are responsible for ensuring that pressure and weight are evenly distributed on the rim. The spoke nipples in turn ensure that the spokes are firmly connected to the wheel. In short: without spokes and spoke nipples, your bike would not work. On this page, you can find out what you should look out for when buying bicycle spoke nipples.

These exciting topics and questions await you:

- Spokes and nipples – two essential building blocks of every wheel

- Bicycle spoke designs

- Bicycle spokes and spoke nipples – what you should look out for when buying

- What accessories do I need for changing spokes and nipples?

- Bicycle spokes and spoke nipples – summary

Spokes and nipples – two essential building blocks of every wheel

An uncomplicated technical solution that has been in use for thousands of years – spokes first appeared around 2000 BC. Since then, the idea that thin stays transfer the forces between the rim and the hub of a wheel has proven itself in a wide variety of designs. Spokes have also been an integral part of bicycle wheel designs for over 200 years. The principle behind them is still the same today: pre-tensioned bicycle spokes connect the hub to the rim. They distribute the rider's weight evenly over the rim. This prevents the rim from being subjected to a particularly high load at one point and possibly breaking.

With the very small diameter of bicycle spokes, this is only possible in a spoke braid that is evenly pre-tensioned during centering. The bicycle nipples ensure in detail that the bicycle spokes are evenly and firmly connected or tensioned to the rim. Bicycle spokes and nipples are therefore two essential components of every bicycle. The spoke nipple is a hollow nut with a collar that can be screwed onto the spoke and is held against the rim. Both spokes and nipples should always be intact if possible. If the spokes break, the wheels can become so badly deformed that you can no longer continue riding and, in the worst case, even fall. But before it gets that far, you can fit a new spoke and nipple in just a few simple steps.

Bicycle spoke designs

There are many different types of spokes on bicycle wheels. We therefore differentiate between spoke profile, spoke bend and spoke thickness.

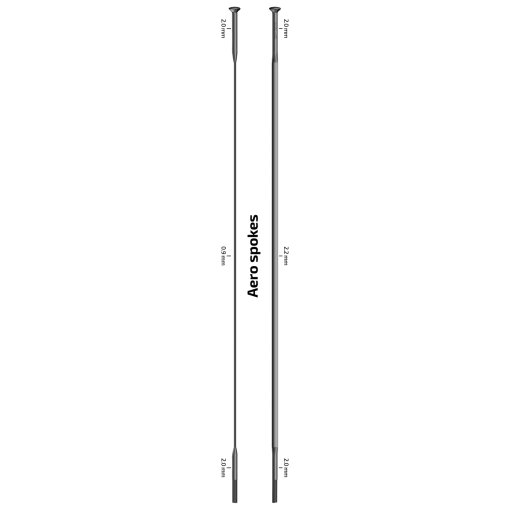

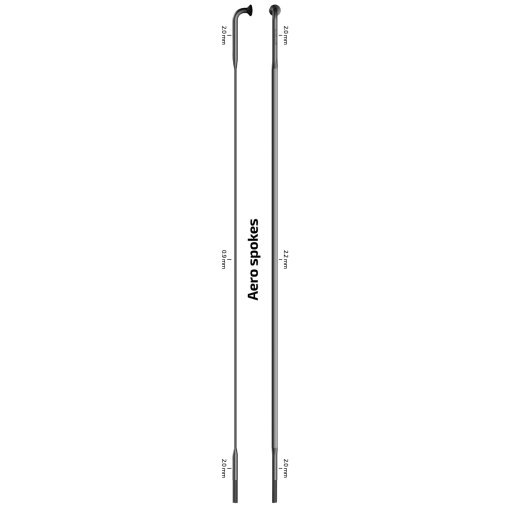

These spoke profiles are available:

- Round spokes: Spokes with a round profile – the most common form

- Blade spokes (also called flat or aero spokes): Spokes with a flat, knife-like profile for better aerodynamics

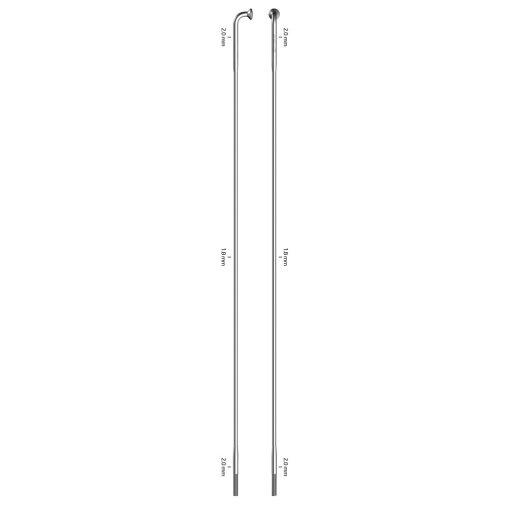

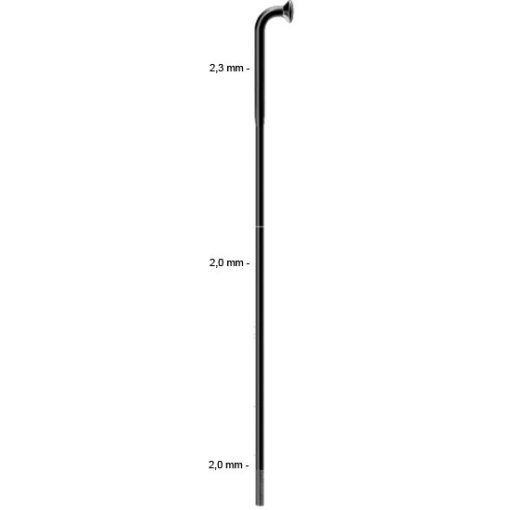

These spoke thicknesses (also tapered or butted) are available:

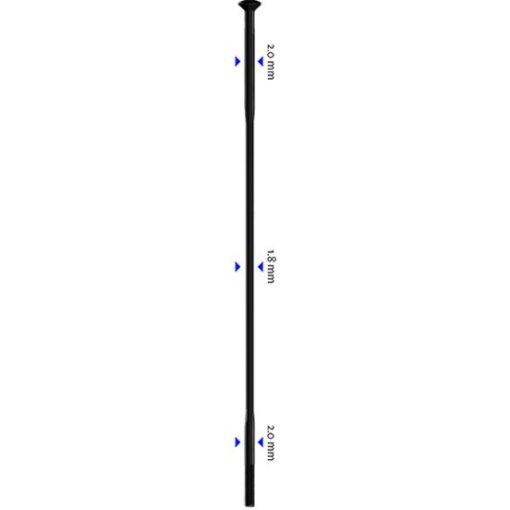

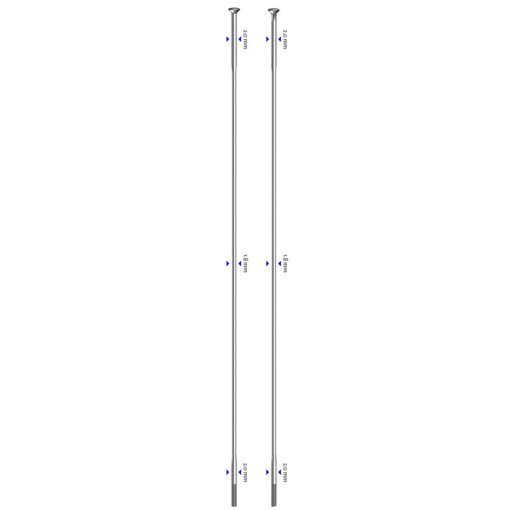

- Smooth spokes (also known as standard spokes): Spokes that do not have any thickening or tapering. Usual diameter: 2.0 mm

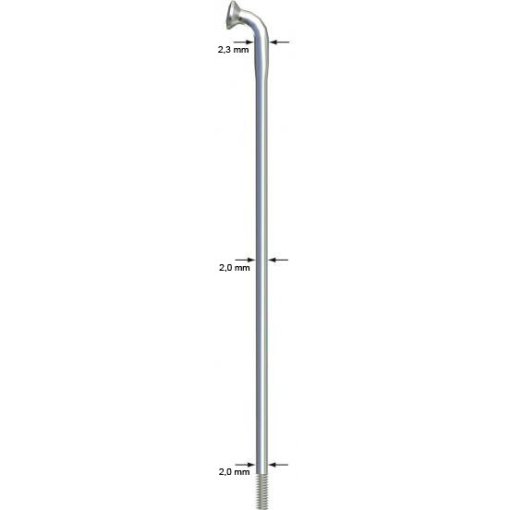

- Thickened spokes: Spokes that are reinforced in the spoke bend. Usual diameter in the bend: 2.3 mm or 2.34 mm

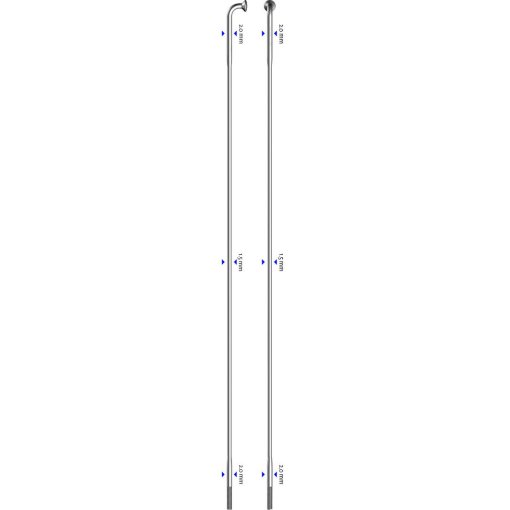

- Double-thickness spokes: Spokes with a thin center section. The diameter at the spoke bend is often 2.0 mm

These spoke bends (also spoke shape) exist:

- J-bend spokes: Bicycle spokes with a bent head – the most common shape

- Straight-pull spokes: Bicycle spokes with a straight head – often found on streamlined blade spokes

Bicycle spokes and spoke nipples – what you should look out for when buying

When buying bicycle spokes, there are a few points you should consider. First of all, you need to know which version you need according to the criteria mentioned above. It's not just about the type of spokes, but also their dimensions. Spokes have different lengths and diameters depending on the wheel and wheel manufacturer.

The same applies to spoke nipples in terms of compatibility, which are available in different lengths and with different heads. Nipples with the thread standard 2 mm and 3.23 mm square are very common, for example. The material used for such a small part as the spoke nipple is also exciting. Most bicycle nipples are made from brass or aluminum. Aluminium nipples are lighter, but require a little more dexterity when building wheels.

In addition to the sizes mentioned above, the choice of spokes naturally also depends on the area of application. MTB spokes for downhill bikes are usually more stable than road bike spokes, for example. Nevertheless, MTB spokes are not the most massive representatives – cargo bikes and rickshaws are really heavy-duty when it comes to nipples and spokes.

The best-known spoke manufacturers such as DT Swiss and Sapim have specially adapted bicycle spokes and nipples in their range depending on the requirements.

What accessories do I need for changing spokes and nipples?

When it comes to tools and accessories, you should have a wheel truing stand. This is the basic requirement for truing wheels and spokes, as it ensures that the wheel runs straight and true in the end. A tensiometer for measuring spoke tension is also practical. The spoke gauge in turn measures the length of the spokes. The spoke wrench, also known as a nipple tensioner, is indispensable in any case. It is used to increase or decrease the tension of a spoke.

You can of course find all of these tools – as well as a large selection of different bicycle spokes and spoke nipples – in your favorite bike store.

Bicycle spokes and spoke nipples – summary

- Bicycle spokes and spoke nipples are two essential components of a bicycle.

- Bicycle spokes connect the hub to the rim, while bicycle nipples ensure that the bicycle spokes are firmly connected to the rim.

- There are different types of bicycle spokes, each with their own advantages and disadvantages.

- When buying bicycle spokes and spoke nipples, you should pay attention to the correct dimensions.

- You will also need some special tools to change the spokes.